US Wind offshore met-mast to deploy 'twisted jacket'

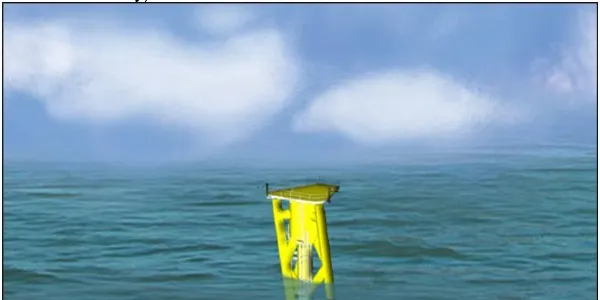

US offshore engineer Keystone has landed the contract to design a "twisted jacket" foundation for a meteorological mast being installed off Maryland at the site of a planned 500MW wind farm being developed by US Wind Inc.