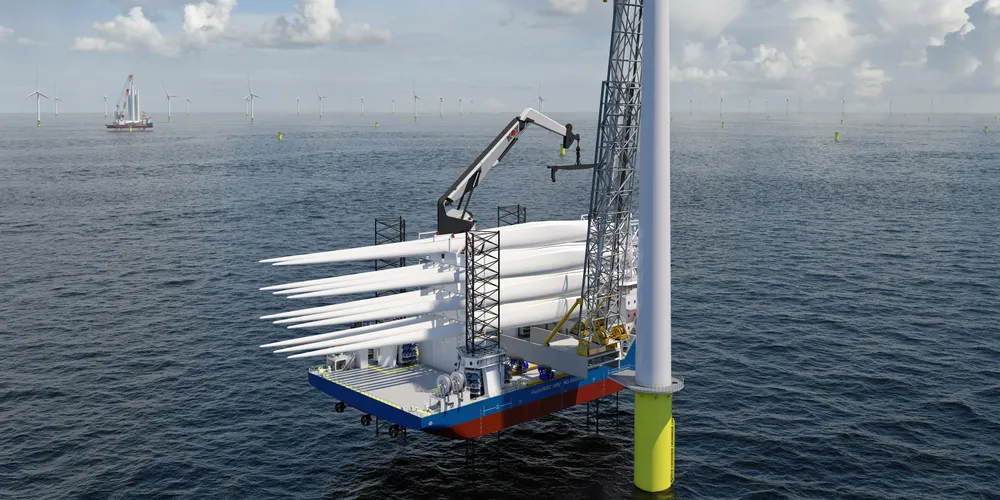

Offshore rotor blade bolt-on operations get tailwind from GustoMSC 'seahorse' technology

Novel Sjøhest concept uses converted jack-up vessel equipped with a small handling crane, trolley, and telescopic leader boom that 'connects and aligns' with the tower, making for quick assembly even in harsh weather