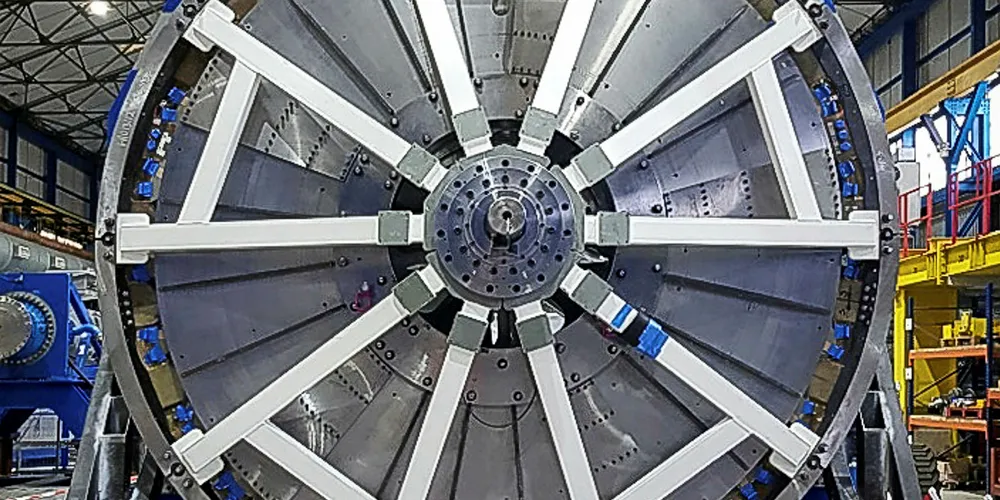

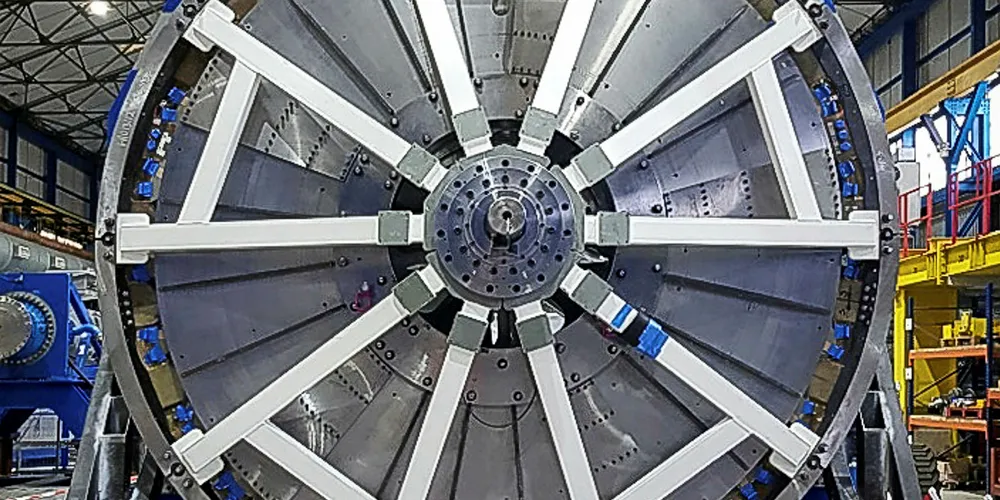

First trials of ‘rare-earth free’ PMG clear scale-up toward 12MW

Tests on 1MW rig in UK show ‘excellent correlation’ of generator performance with computer modelling, says developer

Tests on 1MW rig in UK show ‘excellent correlation’ of generator performance with computer modelling, says developer