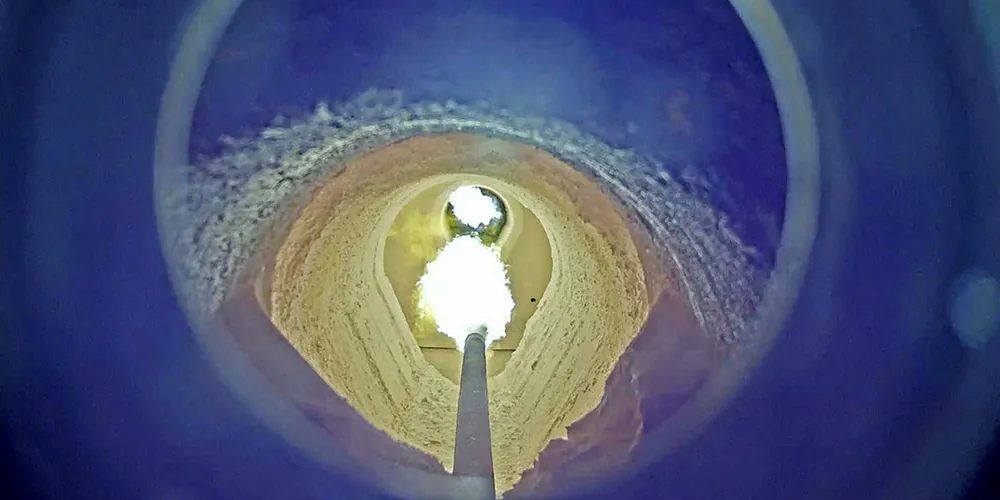

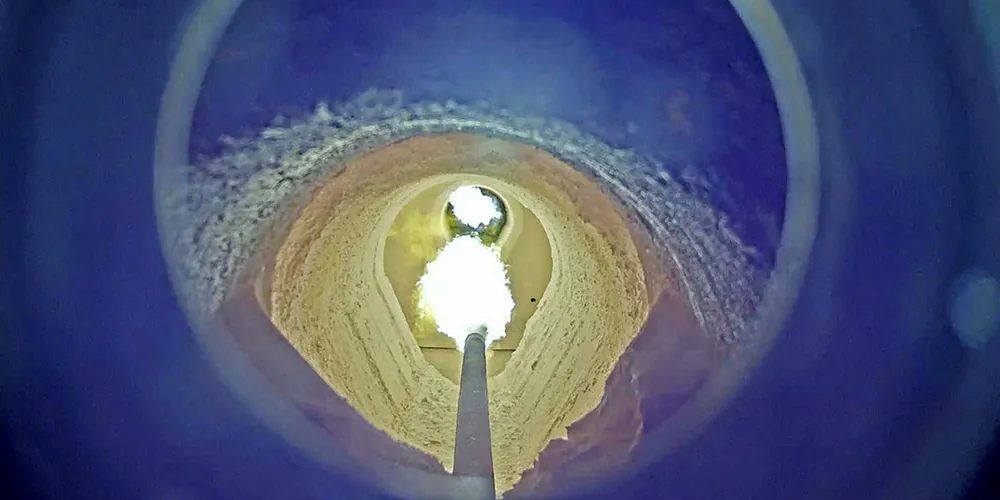

Vattenfall-led project produces world’s first fossil-free iron ore pellets

Fossil-free pellets are a first step by the HYBRIT initiative to offer first decarbonized steel to the market in 2026

Fossil-free pellets are a first step by the HYBRIT initiative to offer first decarbonized steel to the market in 2026