Nel to slash cost of electrolysers by 75%, with green hydrogen at same price as fossil H2 by 2025

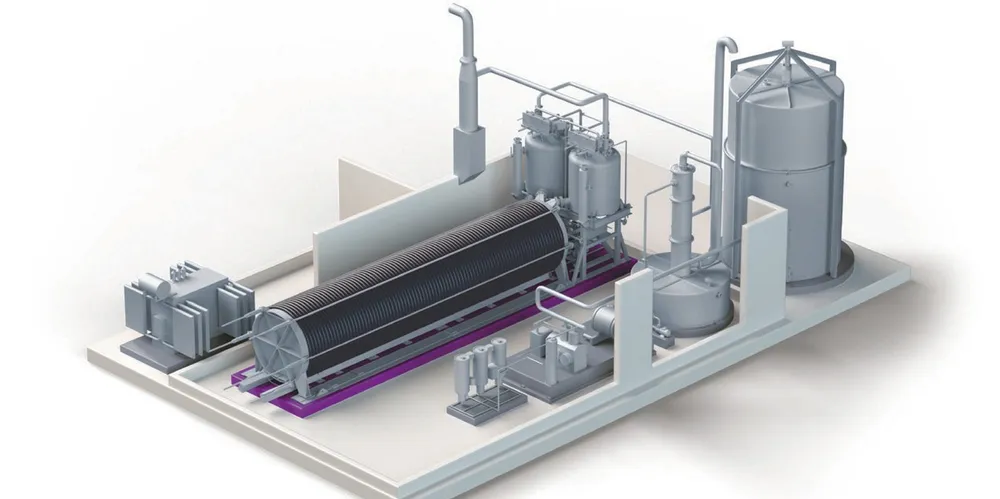

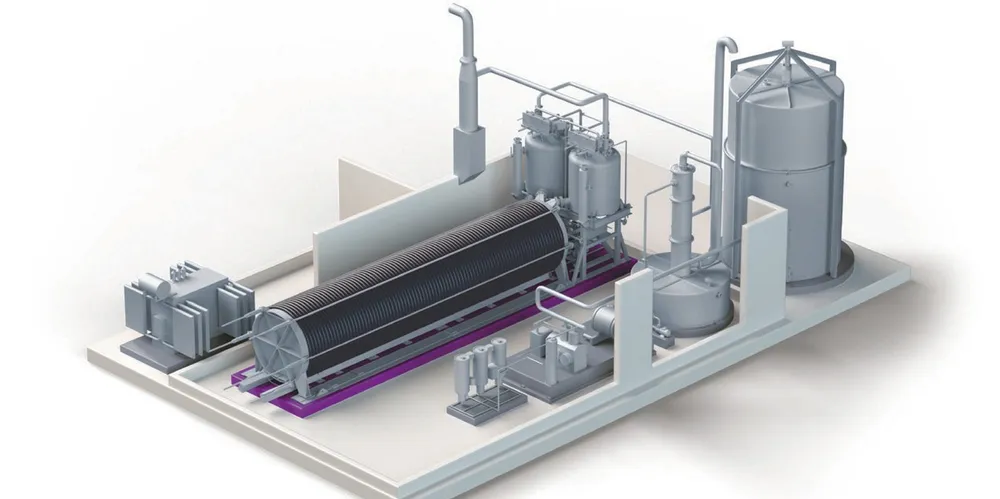

Manufacturer is building a new fully automated electrolyser factory in Norway, which will be expanded to 2GW, resulting in huge economies of scale

Manufacturer is building a new fully automated electrolyser factory in Norway, which will be expanded to 2GW, resulting in huge economies of scale