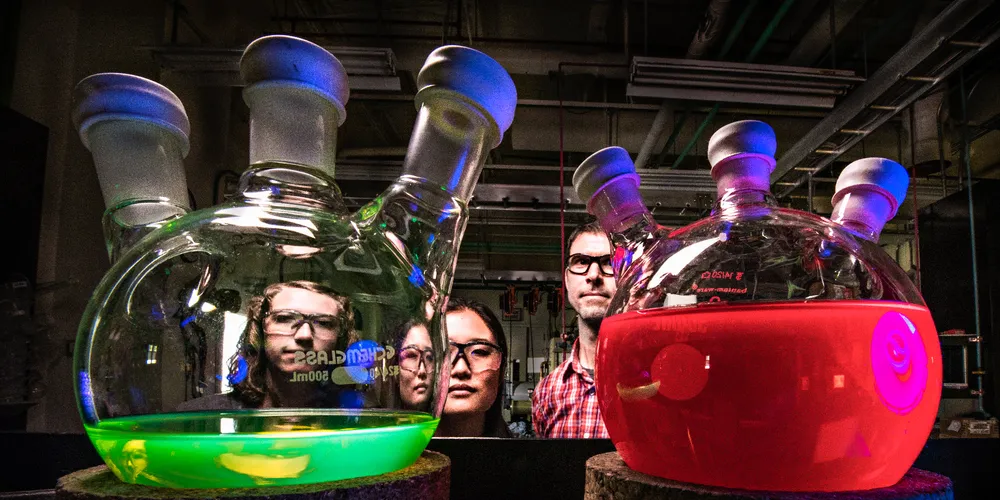

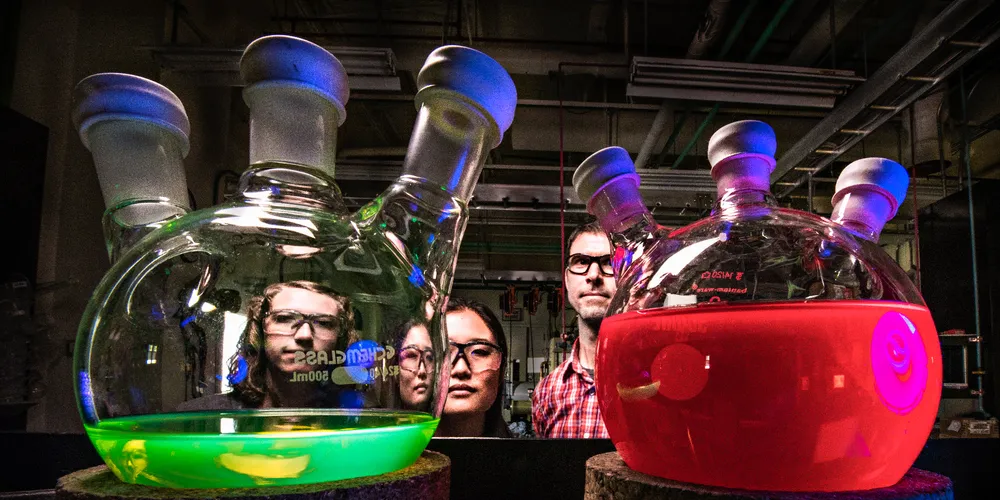

IN DEPTH: Perovskites – solar's next big breakthrough?

For an industry in which technological progress is often measured in tenths of a percentage point, recent progress on perovskite-based PV cells holds the promise of a giant leap forward.

For an industry in which technological progress is often measured in tenths of a percentage point, recent progress on perovskite-based PV cells holds the promise of a giant leap forward.