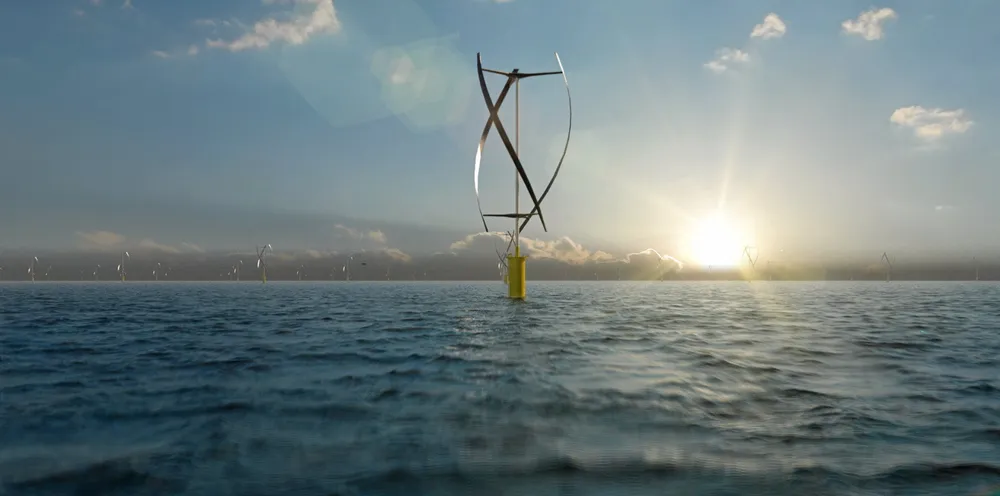

'Supply chain innovation can pioneer a zero-waste offshore wind industry'

Offshore wind's true potential lies beyond clean-power production in the role it can play in spurring a spin-off circular economy, writes Chris Hill

Offshore wind's true potential lies beyond clean-power production in the role it can play in spurring a spin-off circular economy, writes Chris Hill