'We have long been a "molecule company" but that molecule is changing': Technip Energies CTO

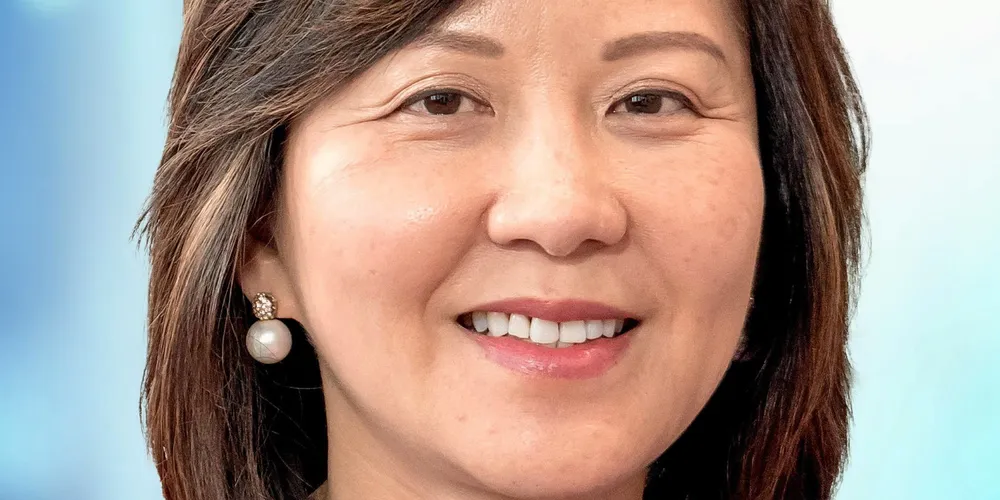

The energy transition is altering the once pure-play oil, gas and petrochemicals contractor 'in every way' and taking it into floating wind power, hydrogen, carbon capture – even running shoes 'made from CO2', Wei Cai tells Darius Snieckus