Sand, ice and supercritical CO2: innovative long-duration system offers ‘cheapest energy storage yet’

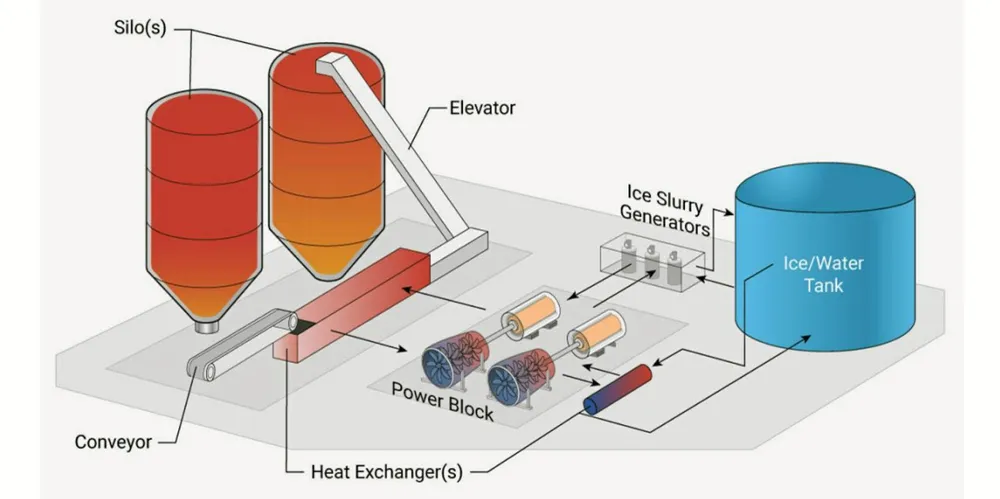

US-based Echogen says its thermal energy storage technology, which can output power for several days straight, will cost far less than batteries and beat long-duration market leader Highview Power on price