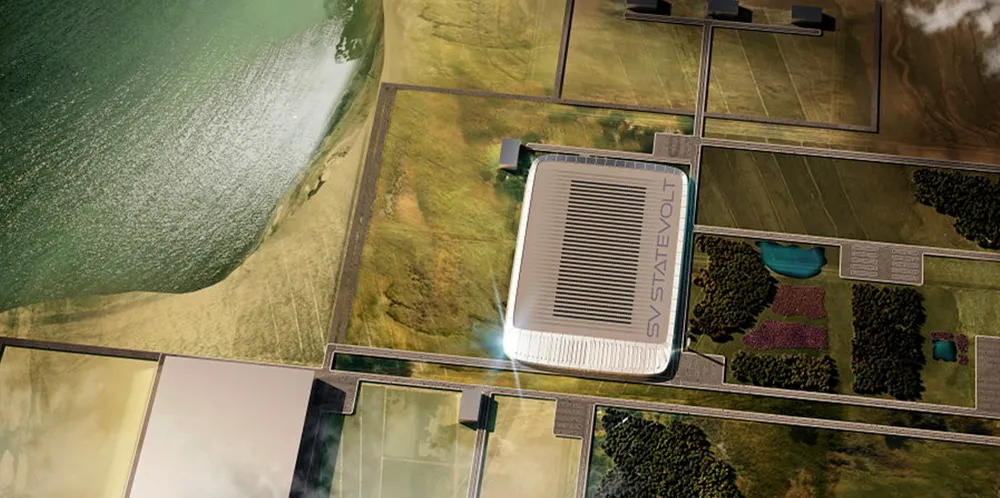

Industrial entrepreneur Carlstrom unveils 'hyper local' $4bn California gigafactory plan

Founder of UK battery-maker Britishvolt launches newest venture, Statevolt, with plan for 54GWh US project that will source lithium and power from local outfit Controlled Thermal Resources