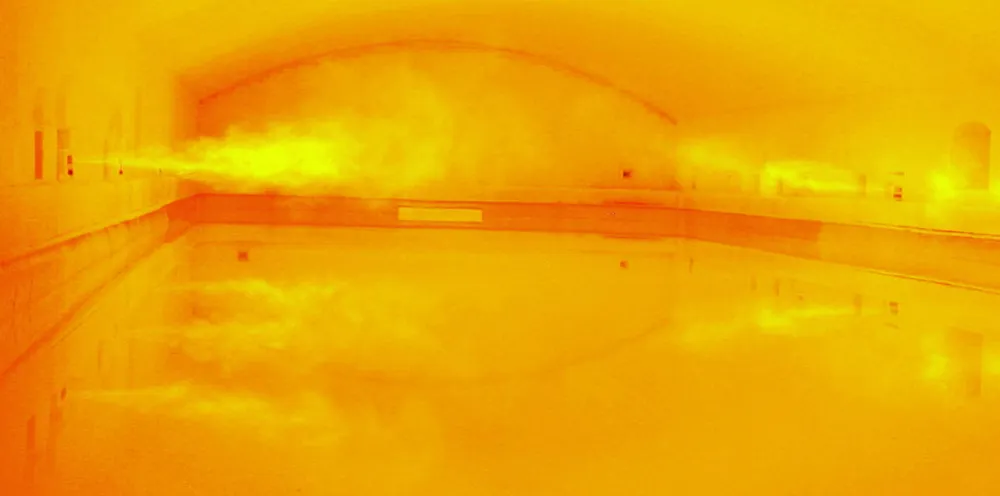

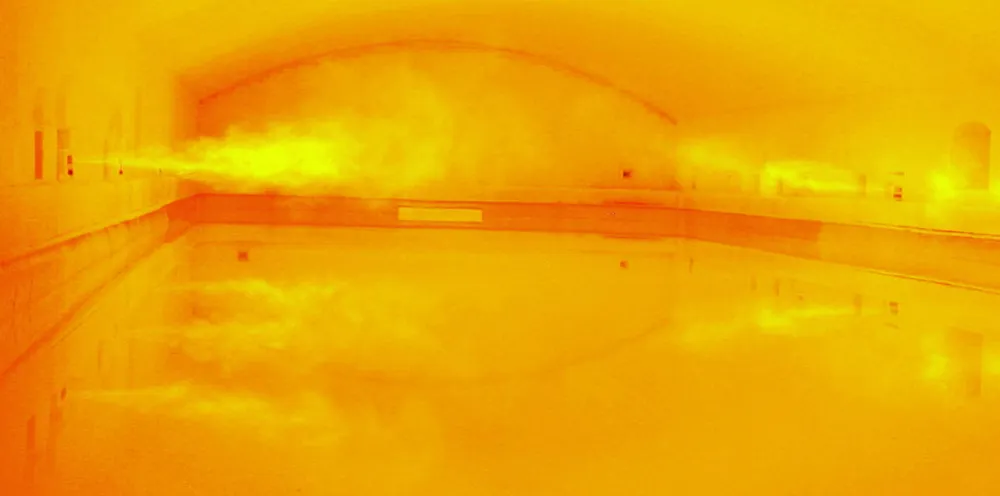

Blow for green glass | Hydrogen reduces product quality when replacing natural gas, pilot finds

H2 indirectly causes discolouration and other issues when used in glass manufacturing, researchers discover

H2 indirectly causes discolouration and other issues when used in glass manufacturing, researchers discover