As this online company description shows, Massachusetts PV firm 1366 Technologies genuinely believes it can change the world — that its proprietary wafer technology will transform the industry and enable solar power to become cost-competitive with coal.

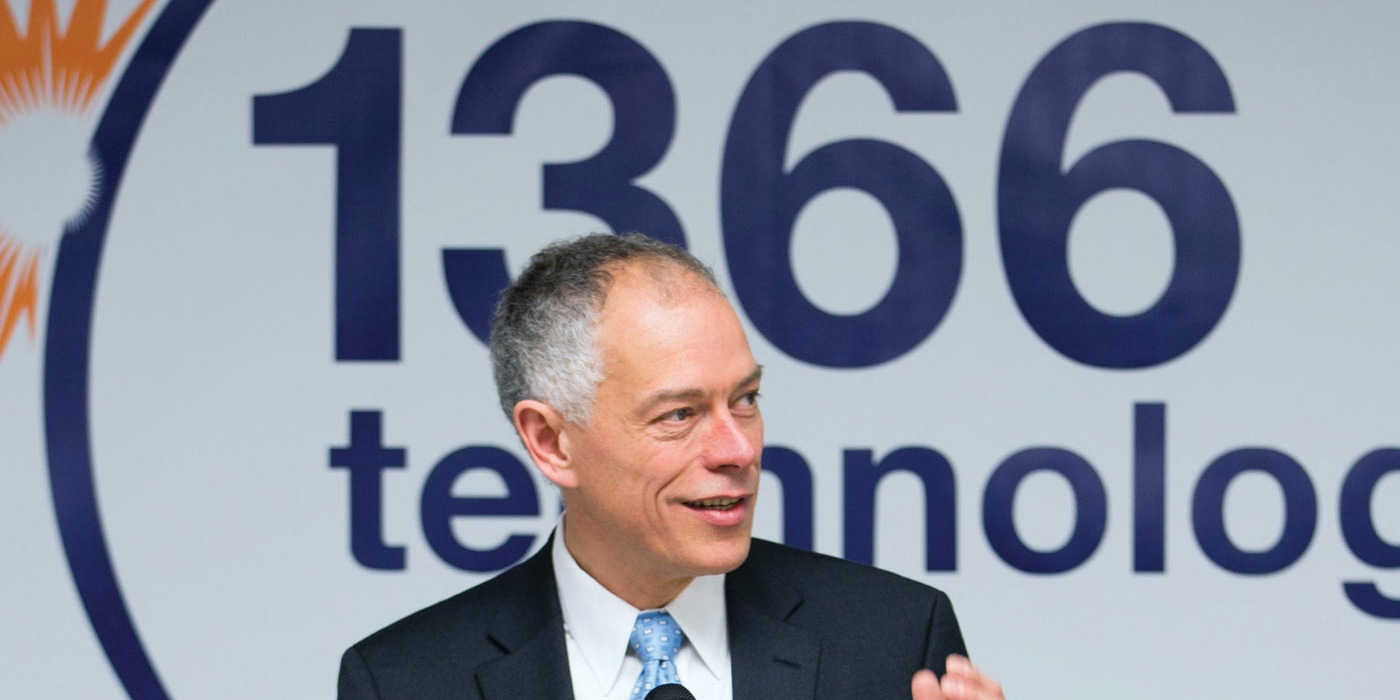

“[We can] supply the world with high-quality wafers produced at a fraction of today’s cost,” chief executive Frank van Mierlo tells Recharge. “We think that we can cut the cost of wafers by a factor of three.”

The